R & D Department

R & D

The general policy of our R & D department include carrying out R & D activities in order to

- Keep up with the technological developments and the market conditions in accordance with the inquiries from the customers,

- Perform cost and quality improvements,

- Improve occupational safety and ergonomics in the factory,

- Design or improve the molds used in casting according to customer specifications and PU system properties,

- Assess the programs from various funds that provide financial aid for scientific and technological R &D projects.

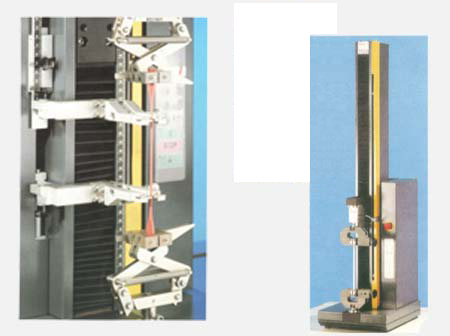

Mechanical R&D - Designing all the molds manufactured on site using CAD/CAM software.

- CNC machines are used for the machining of the molds

Chemical R & D - Research and synthesis of prepolymers using micro and pilot reactors.

- NCO % Analysis

- Tests on physical properties of cast polyurethanes

TESTS AND STANDARDS APPLIED | TESTS | STANDARDS |

| Hardness | DIN 53505 |

| Elasticity Modulus | DIN 53504 |

| Tensile Strength | DIN 53504 |

| % Elongation | DIN 53504 |

| Tear with and without nick | ISO 34-1 |

| Resilience | DIN 53512 |

| Abrasion | ISO 4649 |

| Compression Set | ISO 815-1 |

| Specific Weight | |

Successful TUBITAK (Scientific and Technological Research Council of Turkey) Project

Successful TUBITAK (Scientific and Technological Research Council of Turkey) Project We have successfully concluded a project (No: 714246) named “TDI based Prepolymer Production”, backed by TUBITAK. Inspired by this achievement we are working on new projects in order to serve our customers and ensure higher added value.